Assignment 2 Ferrari

My group members:

Jiayu Li

Qian Sha

Qiutong Zhang

Ruilin Qin

Shanshan Zhang

&

Zhenlei Yu, which is me.

1. Open the Ferrari 250 GTO model using 123d Make and manage the size of the model. As we planned to use 900 x 600 mm mdf , we manage our car into 700 mm long while the width and the height is linked to the length so that the Ferrari can keep in original proportion.

Then 123d Make helps us to divide the model into pieces and we can export the drawings.

2. Change the drawing document into the illustrator format so that we can print the drawings into mdf pieces using laser cut machine. Then assemble the pieces in to the mdf Ferrari.

At first, we forgot to manage the thickness of the mdf board in 123d Make and we cant assemble the pieces together. Then we changed the thickness into 3.1 mm so that the gaps are slightly bigger than the thickness of the mdf board and reduce the friction force while assembling. Therefore, we get this mdf Ferrari. We managed the model into more pieces so that the flow of the appearance is more fluent and smooth.

3. Cover the model with masking tape first to make the model more fixed and then cover with tracing paper. Then divide the car into 8 parts and draw the boundary lines between each part. Take off the tracing paper and cut the aluminum sheets into the same shape of each part but slightly bigger than the traced drawings.

3.5. The 8 parts are the 4 parts over the 4 wheels, the front part, the back part the cover engine between the 2 front wheels and the top cover of the car. I am responsible for the part of the right hand side front wheel.

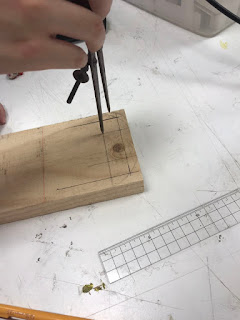

4. Firstly, I put my aluminum sheet near the right side over and gently 'knock' the sheet so that I can know the actual place where I should bend the sheet to fit the shape of the mdf model.

5. Secondly, I used the supporting item with round head to shape the head part of sheet so that it can become round and cover the front of my part.

6. After the 2 basic steps of shaping the aluminum sheet, the rest part is similar, which is keep repeating the shaping work, which is hammering on either the sand bag or the fixed supporting item and put it back to the mdf model to see whether it is exactly fit to the model.

I found that the sheet is bigger while hammering the sheet because of the extension of the sheet as well as the original larger size of the sheet. Therefore, sometimes I cut the extended part off to fit the size.

7. Finally, I used English wheel to smooth the surface of the sheet after the shape is same as the part on the mdf model. And we finally decided to polish the sheet surface using Brasso.

My part.

Assemble my teammates' work and then we got the car.

Jiayu Li

Qian Sha

Qiutong Zhang

Ruilin Qin

Shanshan Zhang

&

Zhenlei Yu, which is me.

1. Open the Ferrari 250 GTO model using 123d Make and manage the size of the model. As we planned to use 900 x 600 mm mdf , we manage our car into 700 mm long while the width and the height is linked to the length so that the Ferrari can keep in original proportion.

Then 123d Make helps us to divide the model into pieces and we can export the drawings.

2. Change the drawing document into the illustrator format so that we can print the drawings into mdf pieces using laser cut machine. Then assemble the pieces in to the mdf Ferrari.

At first, we forgot to manage the thickness of the mdf board in 123d Make and we cant assemble the pieces together. Then we changed the thickness into 3.1 mm so that the gaps are slightly bigger than the thickness of the mdf board and reduce the friction force while assembling. Therefore, we get this mdf Ferrari. We managed the model into more pieces so that the flow of the appearance is more fluent and smooth.

3. Cover the model with masking tape first to make the model more fixed and then cover with tracing paper. Then divide the car into 8 parts and draw the boundary lines between each part. Take off the tracing paper and cut the aluminum sheets into the same shape of each part but slightly bigger than the traced drawings.

3.5. The 8 parts are the 4 parts over the 4 wheels, the front part, the back part the cover engine between the 2 front wheels and the top cover of the car. I am responsible for the part of the right hand side front wheel.

4. Firstly, I put my aluminum sheet near the right side over and gently 'knock' the sheet so that I can know the actual place where I should bend the sheet to fit the shape of the mdf model.

5. Secondly, I used the supporting item with round head to shape the head part of sheet so that it can become round and cover the front of my part.

6. After the 2 basic steps of shaping the aluminum sheet, the rest part is similar, which is keep repeating the shaping work, which is hammering on either the sand bag or the fixed supporting item and put it back to the mdf model to see whether it is exactly fit to the model.

I found that the sheet is bigger while hammering the sheet because of the extension of the sheet as well as the original larger size of the sheet. Therefore, sometimes I cut the extended part off to fit the size.

7. Finally, I used English wheel to smooth the surface of the sheet after the shape is same as the part on the mdf model. And we finally decided to polish the sheet surface using Brasso.

My part.

Assemble my teammates' work and then we got the car.

Comments

Post a Comment